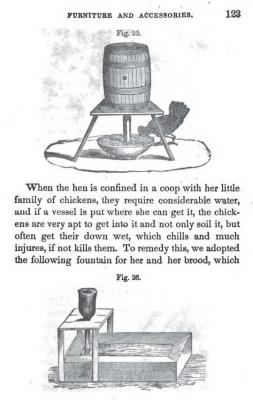

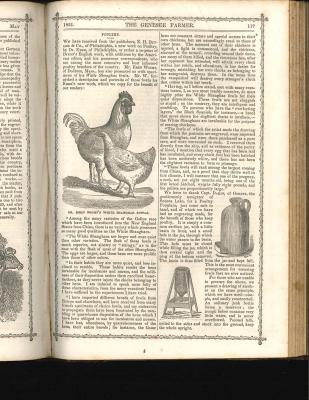

Sometimes called poultry fountains, but commonly called chicken waterers, these devices of various designs and materials have been in use for a long time. The concept is to have a reservoir of water with a small outlet at the bottom which allows water from that container to flow into a tray or dish at the base. If the level of the water in the tray is above the hole in the container, air can not enter the reservoir and no more water can flow out. As the chickens drink from the tray, the water level recedes which allows air to enter the container holding the water reserve, and permits water to flow out and fill the tray again until the water level covers the exit hole.

A device like this is needed for chickens and other poultry because just putting water in a trough or bowl would quickly be dirtied by the poultry walking in it. If the water is for small chicks, they could easily fall into a larger trough or bowl, and drown or get sick from being wet and cold. The described design made it safer for chicks and kept the water cleaner for all poultry. The same design principles are employed in many of the chicken waterers available for purchase today in your nearby farm store.

Below are several illustrations of early examples, found in publications dating from 1845 and 1851. Variations on these devices could have been in use well before these dates, but these are the earliest I’ve found so far.

Based on these early illustrations coopers were involved in making the container or receptacle used as the water reservoir. Or, perhaps more likely farmers used whatever materials were available.

These were followed by pottery waterers, hand-thrown by the regional or local potter. Waterers of this design could have been two pieces that would have started out as a jug. There would be a small hole at the bottom of the jug and the opening at the top would most likely have been plugged.

After being filled with water, the 'jug' would be place in a dish, resembling a pie plate. As long as the hole near the bottom of the jug was lower than the top lip of the dish, water would fill the dish but stop flowing out of the jug before overflowing the dish.

Though sometimes the bowl or dish at the base was made by just pushing in part of the jug wall, and then extending the inner jug wall down lower than the base rim, as in the example below. This created the dish portion as part of the jug, not requiring a second piece to make it functional.

In other cases the top jug and the bottom plate are created as one-piece by the potter, as in this example made by Austin. L. Hyssong, Bloomsburg, PA. (CW142)

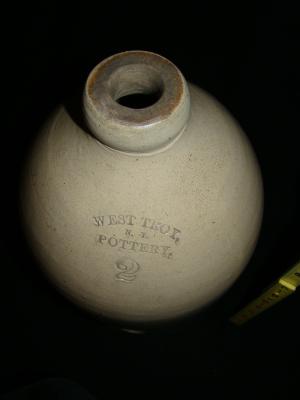

The top of the jug could have been sealed during making, or left open to be used as a fill-hole and then corked securely to not allow any air to enter after the jug was filled with water. This West Troy Pottery waterer (CW127) has an open top, which is a bit unusual.

Later the waterer was molded like jugs, rather than hand-thrown, and then modified again to make it into a chicken waterer. Today, the vast majority of the chicken waterers found are molded, rather than hand-thrown.

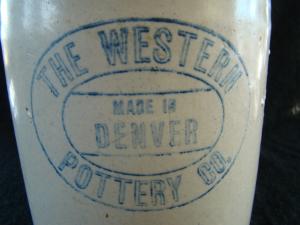

Some stoneware waterers were marked identifying the maker, but many were not. There are dozens of stoneware waterers in my collection that do not have a maker’s mark, so it is very difficult to determine where they were made and by whom. Below are two significant pottery companies that marked some of their products. The Western Pottery Company (CW131) and the Red Wing Stoneware Company.

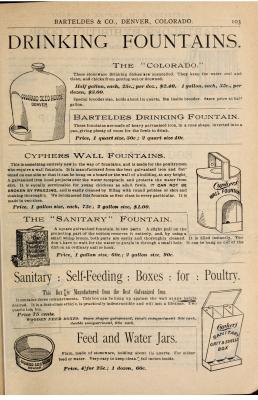

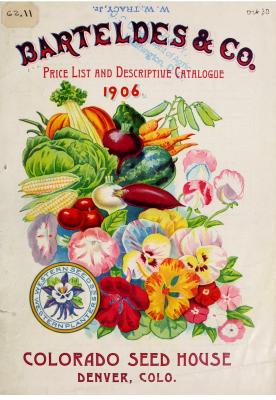

By the late 19th century and into the 20th century, they became advertising pieces, with the name of a business stamped, incised or stenciled on the item. This time was also the heyday of the seed and nursery catalog business. The seed businesses often were targeting the women of the farm family, who grew the gardens and raised the food for the family. They were often also responsible for the farm’s poultry flock. During this time one starts to see poultry and poultry supplies included in the seed catalog. And one of the items available was likely a chicken waterer. Often they were generic and without marks, but sometimes the name of the seed company was on the waterer. See the example below from the Barteldes & Co. seed catalog and the waterer below left (CW072) that was featured in the catalog.

Another example of a waterer used as advertising for a poultry-related company is on the right above. Park & Pollard Co. was a Boston-based feed and grain supply company and Overall was one of their popular chicken feeds. This two-piece stoneware waterer with Bristol glaze and cobalt stenciled mark shows only the top piece.

Most pottery, glass, metal and plastic waterers were made specifically as chicken waterers, complete with the top reservoir and base included . But many different styles of bases were made that accommodated the standard quart canning jar. The canning jar either sat upon the base or it actually attached to the base dish by the treaded top of the canning jar when inverted over the base. Since canning jars were in abundance in every farm home, buying a base that could be fitted with a canning jar resulted in a highly functional waterer at a very low cost to the farm family. Several examples are shown below.

As in many areas of manufacturing, by the mid-20th century plastic was beginning to replace glass. First just the base was made of plastic and later the whole waterer was made of plastic. Bakelite was an early form of plastic that was used.

Today poultry/chicken waterers are still made with the same functionality as was employed in the mid-19th century. Though most are made totally of plastic, one can also purchase galvanized metal waterers today.

The bulk of the waterers in my collection were made in the United States, though I have examples documented to have been made in England and Japan.

I intend for my chicken waterer collection to be representative of the wide array of designs, materials, and time periods. With over 150 items in my collection, only a small portion are represented online. I welcome being contacted about chicken waterers, and look forward to hearing from collectors and others interested in waterers. –Marty Schlabach